Automatic height zeroing on the High-Z S-720

Introduction

This tutorial aims at explaining how to use the automatic height zeroing on the High-Z S-720 CNC machine.

Height zeroing is the process by which the vertical (Z) zero is defined.

General principle

The sensing system consists in a crocodile clamp and a metalic plate.

The functioning principle is that the crocodile clip is used to make contact with the drill bit

and the metalic plate is placed on the surface to use as zero-reference (typically the workpiece)

How To

1. Place the material on the spoil board (la plaque martyr); Insert and fasten the drill bit.

2. Clamp the crocolide clip on the drill bit & place the metalic plate on the surface of the material below the drill bit.

3. Go to the screen "Workpiece origin

4. Select the "auto height adjustement" icon

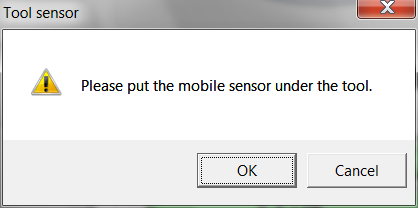

5. On the next sceen, select "mobile sensor, set under the tool" and click "OK".

6. Place the metalic plate under the drill bit and press ok.

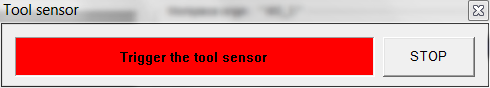

7. Upon the next screen, lift the metalic plate such as to touch the drill bit in order to make electric contact and thus trigger the sensor

8. When the color turns green, place the metallic plate back on the worksurface below the tool. ATTENTION, the CNC is then automatically slowly lowered until it touches the metallic plate again.

9. Once the drill touches the metallic plate on the worksurface, it registers its position and lifts up again. Notice that you do not need to click on "Z-zero".

9. Remove the crocodile clip and the metallic plate.

10. You may now select "drive to 0" and check that the height is correctly sensed.

Info

Difficulty: ●○○○○

Last updated: October 2020