My formation at fablab

First and second days:

During these two days at the Fablab we got a chance to become familiar with different machines such as 3D printers, a laser and a milling machine. The tutor explained the use of each machine with a lot of examples. He described his career and how he arrived at the Fablab. We were print our designs. That allowed us to learn fow to work on various programs.

Third and fourth days:

Here, I wanted to print a 3D pokemon, called “évoli”. I chose to print in PLA with the CARA software. The software and the machine were very simple, but very slow. It takes around one hour. Width: 3cm; Length: 5cm and height: 4cm. The result was not bad, although I chose normal quality and not optimal, owing to lack of time. The object was still very fragile and could break quickly. An ear disappeared during the cleaning of the supports.

Next prototype :

I decided to make a train, using the laser. I don’t have many pictures, because the protective glass was dirty. In the first, I drew the plans on the ILLUSTRATOR software, that I imported in .DXF.

After that, I was on the software “123 Make by Autodesk”, and on to cutting!

After, I assemble of the different parts together with glue. There’s the final result:

Next prototype :

Here, we seetle forte principe higher one. But a feanelicol design. For this one, the cuttings being very close, I had to deheose the power of the laser. I didn’t want to burn the wood, which was of 4mm thick.

Next prototype :

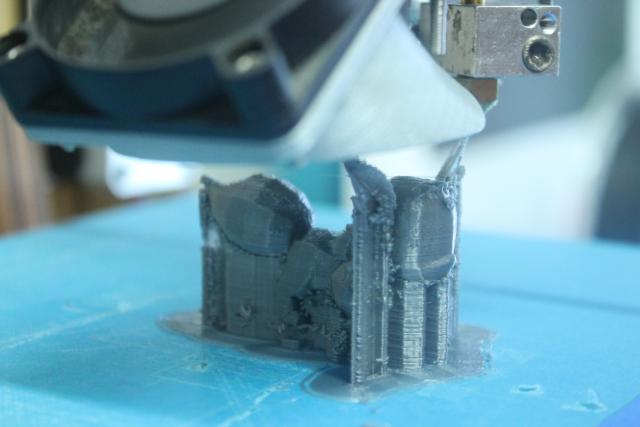

For my last prototype, I decided to make owls. And I used the 3D printer. Not the previous with “PLA” plastic one but with the “ABS” plastic. This one is a bit harder to work with, but the result is stronger and more beautiful.

It took around two hours to finish my owl. Width: 4cm; Length: 4cm and height: 6cm.

Indeed, this one doesn’t require cleaning and the result was perfect for me.

In conclusion, I feel these four days were very enriching and gave me the chance to use the machines.

Info

Date: November 2016

Last updated: January 2017