Fixing the CNC Milling: iMAL High-Z S-720

One of the reasons why you have to stay close to the milling machine while it is in use is that things can and will go wrong.

This howto explains how to detect and resolve an issue with the brushes.

01 Initial symptoms

None of the milling parameters we used to mill succesfully with seemed to work

Each time we increased the milling speed the machine made either weird sounds or produced weird milling chips

Eventually the spindle stopped spinning completelly in the middle of a sequence.

02 How to inspect

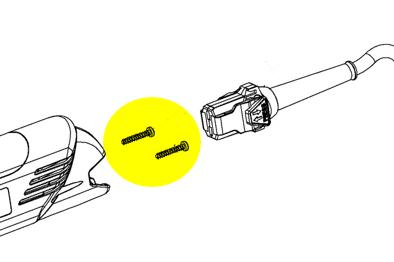

To open up the spindle, 2 torx screws at the top of of the machine have to be removed

03 What to diagnose

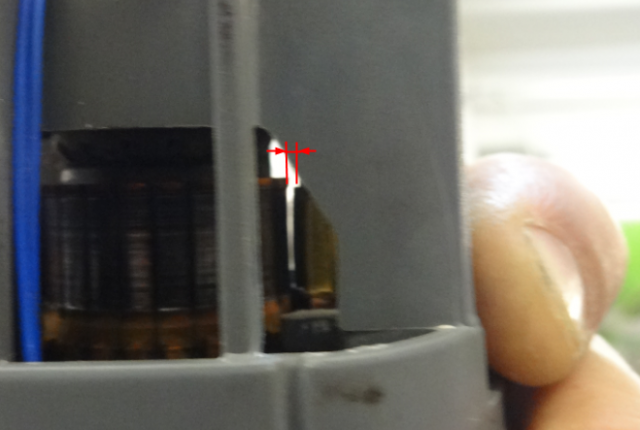

Once the the spindle was opened up, It was obvious that the brushes no longer made contact with the rotor.

They were worn off due to constant milling.

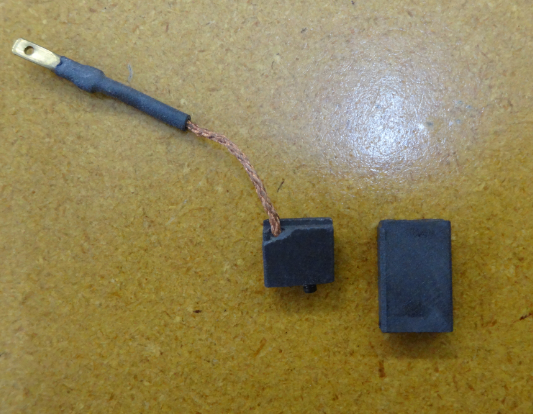

a new brush compared to an old brush

04 How to fix

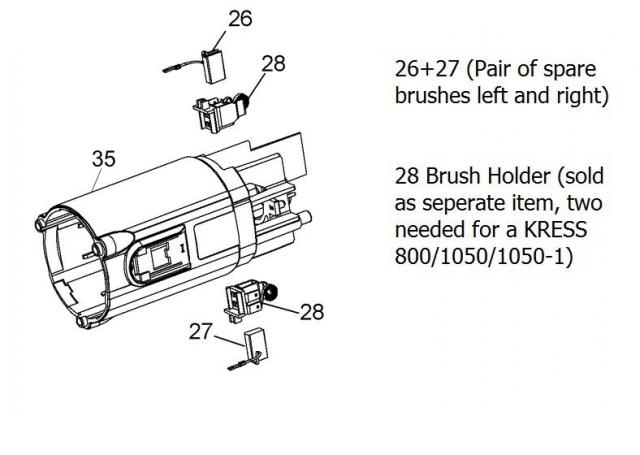

We ordered immediately a new pair of brushes, searching for "AMB (Kress) Spare Brushes Pair (26&27)". They where €12,50/pair at https://www.damencnc.com/en/amb-kress-spare-brushes-pair-26-27/a226

Replace the old brushes with the new ones and continue milling!

Info

Date: December 2019

Last updated: December 2019