Fablab Chessboard

Fablab chessboard

During a 4-day workshop in IMAL through experimentation with machinery and materials the chessboard was made. The chessboard-project consists of 3 different minor projects (chess pieces, chessboard and a mold holding the pawns) made by using CNC- & Lasercut- machinery.

Chess pieces:

The main idea of this project was creating chess-pieces by use of the lasercutting machine based on two key factors; firstly, they mustn’t feel like flimsy multiplex, wooden sheets. Secondly no additional materials/glue are to be used.

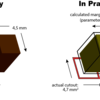

The look and feel of pawns: By layering 3 laser-cut sheets and joining them together with a small securely fitted wooden beam, 3 Dimensional pawns are created which look and feel like they’re made of a single piece. This was possible by studying the behaviour of the the laser (the removed margins of the cut material). In conclusion to this study, approximately 0,1 millimeters are lost on each side of of the lasered object. This means that the width of the wooden beam has to be lasered at a width of 4,9 mm to securely fit a hole lasered on 4,5 mm.

The mold:

By offsetting the 2D-design of the pawns and cnc-engraving these surfaces a cutout is created for the chess pieces to be placed in securely. The mold tightly fits the chessboard, so it rests secure when it’s stored.

The chessboard:

By experimentation with flex-cuts, the perfect flexibillity can be applied to the 3mm multiplex borders of the chessboard. This makes that the corners of the chessboard can be curved. By curving the wood and securely fitting joints between the top & bottom panels, a ‘cabinet’ which is easily opened & closed is created.

Unfortunately due time restrictions and miscalculations within the project file, the chessboard wasn't completed. The curved edges (& cabinet functionality) are not added to the board yet.

Info

Date: January 2021 - February 2021

Last updated: February 2021