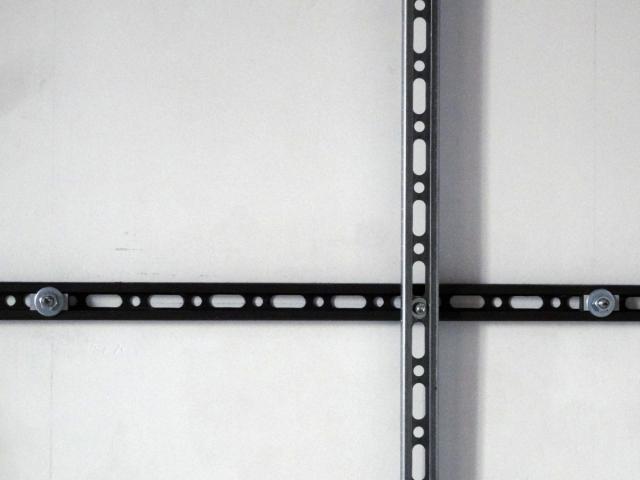

C-Rail insert (M8) // WLS_00_M_24L4OLR

"These inserts are used together with c-rails to prevent them from colapsing in case the rail is mounted using a (m8) nut."

- Category: Building blocks

- Materials: 13mm HPL (Trespa)

- Process: CNC-Milling

- Cycle Time: 1,5pc/min (143prts in 03:32:36 hours)

- Software: Onshape, NanoCAD, Estlcam

- Dimensions : H13 mm x L30 mm X W23 mm

This insert for c-rails came to existence to protect the c-rails from crumble or deform under the forces applied when tightening the (M8) nuts that attach c-rails to our wall. As an extension to the range of possible uses this insert can also serve as a “back to back” connector as used to build the mezzanine, but then an additional pocket is required to facilitate the T-Nut.

The dimensions of the insert are the result of the importance to fit the inner profile of the c-rails considering the tolerances of the production of the c-rail, as well as the tolerances of the location and alignment of the M8 studs of the wall thus providing a larger center hole. The simplicity/rationality behind the shape of the object is a direct result of the attempt to minimize the cycle time of the object on the milling machine. Milling trough HPL is hard and this insert has no esthetical importance in the whole of the project. To reduce cycle times the pattern in witch the shape is milled is optimized for ᴓ6mm milling bit, where one pass “cuts” 2 shapes. The initial pocket is creates using one “zigzag” trajectory.

Milling parameters:

Type: Flat Endmill

Size: 6mm

Amount of flutes: 2

Material: HSS

Cut Feedtatee: 1000mm/min

Plunge Feedrate: 3000mm/min

Spindle speed: 5

Depth increment: 2mm

"These inserts are used together with c-rails to prevent them from colapsing in case the rail is mounted using a (m8) nut "

Info

Date: December 2018 - April 2020

Last updated: May 2020