3D house & Typo portrait printing

Felix, our guide for two days, explained to us the importance of Fablab in the production of fews articles. Building, furniture, medicine, robotics,... 3D printing is a growing market. FabLab is an American company that provides access to high-tech machines for prototyping at a very low cost.

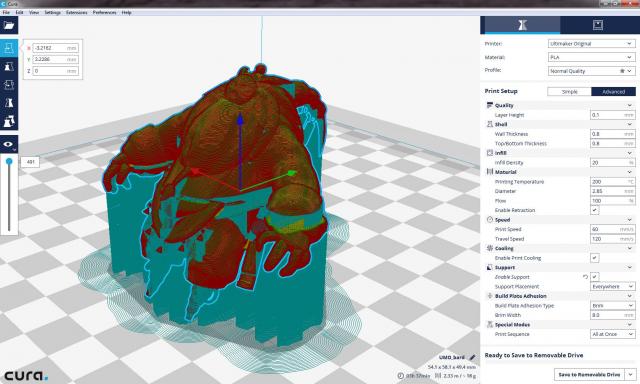

Then we saw the different printing requirements for each process. The material should’nt be harmful and mostly recyclable. Their melting point should be neither too high nor too low. Inaccuracies of the laser printer and his strength. The material used for 3D printing (PLA or ABS) changes in strength, melting point,... Engines that can be controlled "step by step", which means a precise control of the measure. For a 3D printer, preparing models on the software is very important. In our case, we saw how to use Cura to associate model and printer depending on the version.

Finally, we learned to use the machines and techniques were presented. In our case, we worked on three different machines. Engraving, laser drilling and milling printe. They are subtractive because they model by removing material. The laser will burn the material while the miller will remove the material. The 3D printer is additive because it adds material. And the printer in stéréolithographie which begins from a powder cube to solidify parts of the object. Our teacher presented us examples of 3D scans. It gave us a modeling of a 360 degree environment, a system often used in architecture or police investigations (crime scene reconstitution).

Second day :

It was time to practice. Our teacher invited us to prepare our 3D/2D models to print on the best printer. We worked a long time on Maya, Illustrator and Cura to adapt our model for what we wanted. To start simply, I printed a keychain. They warned us that models printed on the 3D printer with supports weren’t clean everytime. Then we prepared a 2D model to be printed with a laser and given the conditions for a good impression. Differentiated features, color to separate the layers, the laser strenght not to pierce the plate.

Third Day :

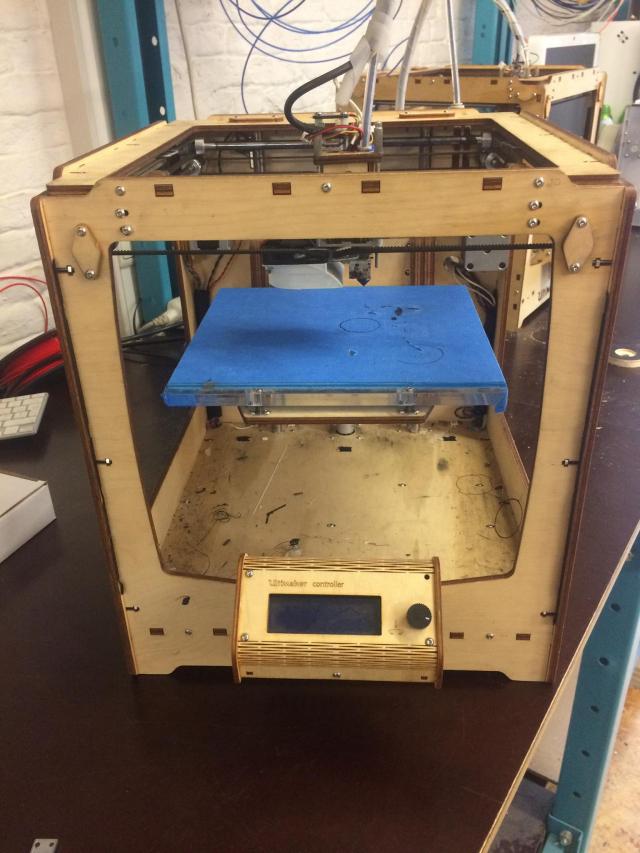

Our work continues with our new trainer ! This time we put the finger the printer settings problems. Whether 3D or laser, printing necessitated primordials presets and a rigorous supervision. Laid back support, crushed material, lack of thread. There was something for every taste. Let’s get to the facts.

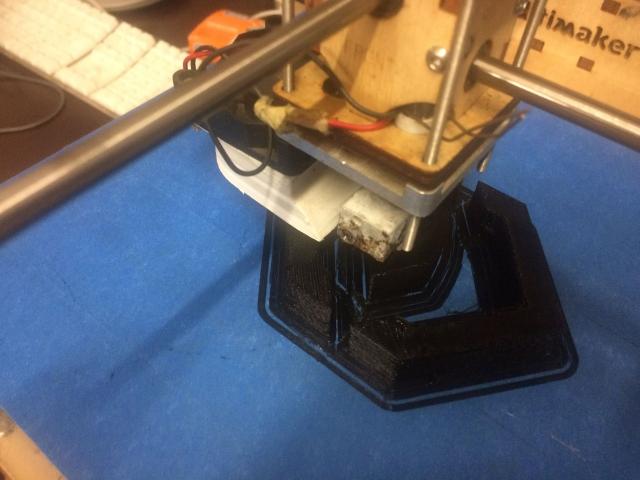

Among the problems I had, there are those that came from the printer and those that came from me. That day, three problems happened to me to print my 3D house. First, the extrusion temperature of the machine wasn’t good while the value was posted. A problem solved by waiting for the machine to interpret the information. Second round, the print base of the object was lifted. Error or bad luck, an additive spray on the printing table was enough to solve the problem. Last round, the extrusion head crushed the printed matter like a pancake. A preset error of the diameter expected to file the matter, which I was the cause of. Overall, errors of any kind require to restart the printing to be resolved.

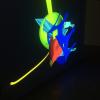

For me, the laser printer is the simplest to use. The only difficulty in this printing is the preparation of the vector model if we want to engrave or cut the lines. In my case, I cut my typo portrait. The longest was to join the letters together to get an assembled wooden model. Then, I had to adjust the laser power to drill the wood. Given the heat of the laser, it is sometimes necessary to stop the process to wait that the emerged flame was consumed. I had this problem when I tried to cut a plate of 6 mm instead of 3 mm. Bad idea. The solution was to reduce the speed according to the power. Because of print fail, I printed my drawing on the 3 mm.

Last day :

We polished our pieces to remove the printing supports and other powders. I could start a last printing of a staircase typography and collect all the information for a good printing at school.

Info

Date: October 2016

Last updated: January 2017